CNC machining continues to be a backbone of modern manufacturing because it delivers unmatched accuracy, repeatability, and scalability across industries ranging from aerospace to medical devices. However, even the most advanced CNC machines cannot achieve consistent results without properly engineered workholding solutions. This is where jig and fixture design becomes a decisive factor in machining success. By controlling part positioning, stabilizing components under cutting forces, and reducing setup inconsistencies, well-designed tooling bridges the gap between digital programs and physical production. Manufacturers that invest in intelligent tooling strategies gain not only better part quality but also measurable improvements in efficiency, cost control, and production reliability.

The Role of Jig and Fixture Design in CNC Machining Accuracy

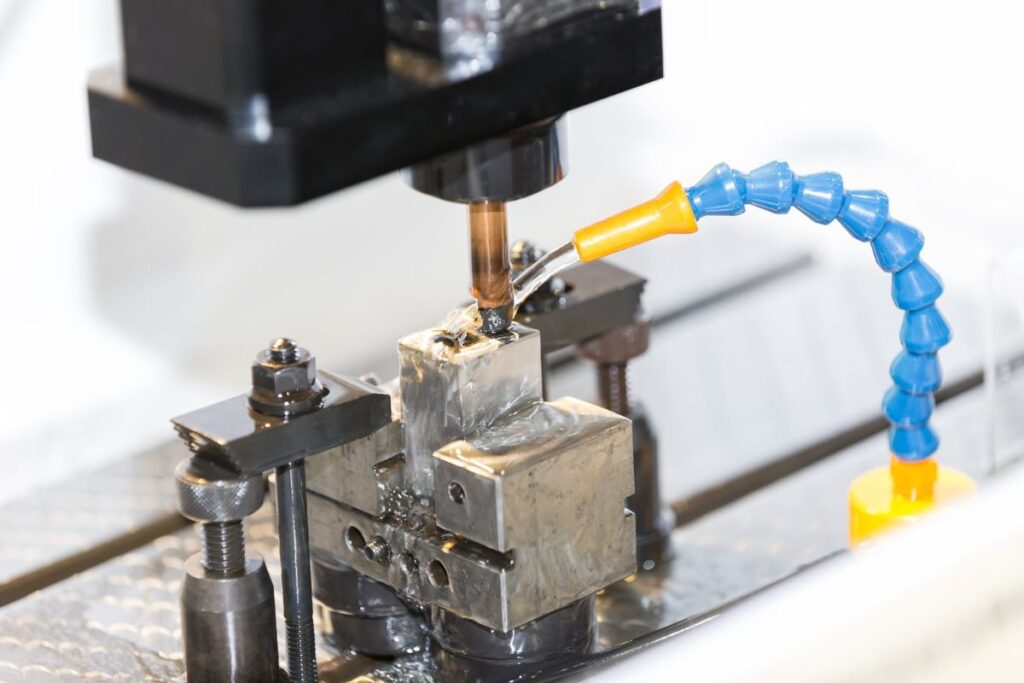

In CNC machining, accuracy depends on more than tool paths and machine calibration; it relies heavily on how securely and precisely a workpiece is held during each operation. Advanced jig and fixture design ensures that parts are located repeatedly in the exact same position, eliminating cumulative errors that can occur over multiple setups. This controlled positioning is especially critical when machining tight-tolerance components or complex geometries where even minor deviations can lead to scrap or rework. By integrating datum references, clamping logic, and accessibility considerations, thoughtfully engineered tooling transforms theoretical precision into practical, repeatable results on the shop floor.

Why Custom Tooling Matters More Than Standard Solutions

While off-the-shelf fixtures can serve basic machining needs, they often fall short in high-precision or high-volume environments. Custom tooling solutions are developed around specific part geometries, materials, and machining sequences, allowing manufacturers to optimize every aspect of the process. When companies adopt jig and fixture design tailored to their production goals, they benefit from faster setups, reduced operator dependency, and improved cycle time consistency. Custom solutions also enable better tool access and chip evacuation, which directly impacts surface finish quality and tool life in demanding CNC applications.

Improving Productivity Through Workholding Tooling Systems

Productivity gains in CNC machining are often associated with faster machines or more advanced controls, but workholding tooling systems play an equally important role. Efficient tooling minimizes setup adjustments and allows operators to load and unload parts quickly without compromising accuracy. By standardizing fixture interfaces and clamping mechanisms, manufacturers can reduce downtime between jobs and improve machine utilization rates. Well-designed tooling systems also support automation, making them essential for lights-out manufacturing and scalable production strategies in competitive markets.

Precision Machining Aids for Complex Part Geometry

As CNC-machined components become more intricate, precision machining aids are required to support complex shapes and multi-axis operations. Fixtures designed for contour-following surfaces, angled features, or thin-walled parts help prevent deformation and vibration during cutting. These aids are particularly valuable in industries where material integrity and dimensional stability are critical, such as aerospace or medical manufacturing. By incorporating adjustable supports, modular elements, and vibration-damping features, modern tooling solutions enhance machining stability while maintaining flexibility for design changes.

Key Benefits of Manufacturing Support Tooling

Manufacturing support tooling extends beyond holding a part in place; it supports the entire machining workflow from setup to inspection. Well-engineered tooling simplifies alignment, reduces the need for manual measurements, and improves operator confidence during production. This results in more consistent output and fewer quality checks required downstream. The strategic use of CNC fixture and jig solutions allows manufacturers to maintain tight process control even as production volumes increase or part designs evolve.

Key advantages of effective manufacturing support tooling include:

-

Reduced setup time and faster changeovers between jobs

-

Improved dimensional consistency across production batches

-

Lower scrap and rework rates due to stable part positioning

Designing CNC Fixture and Jig Solutions for Scalability

Scalability is a major concern for manufacturers planning long-term growth. Tooling designed only for immediate needs may limit future expansion or process improvements. Scalable CNC fixture and jig solutions are developed with modularity and adaptability in mind, allowing components to be reused or reconfigured as product lines change. This approach not only protects tooling investments but also supports continuous improvement initiatives. By anticipating future machining requirements during the design phase, manufacturers can align tooling strategies with broader business objectives.

Reducing Human Error Through Intelligent Tooling Design

Human error remains one of the most common sources of inconsistency in CNC machining. Poorly designed fixtures that require complex alignment or manual adjustments increase the risk of mistakes during setup. In contrast, intelligent tooling design simplifies operator interaction by guiding correct part placement and clamping automatically. Features such as foolproof locating pins, self-aligning clamps, and clear visual references help ensure repeatable setups regardless of operator experience. This reliability is a direct outcome of advanced jig and fixture design principles applied with a focus on usability and process control.

Supporting High-Tolerance Industries With Reliable Tooling

Industries that demand extreme precision, such as aerospace, defense, and medical manufacturing, rely heavily on advanced tooling solutions to meet regulatory and performance standards. In these environments, tooling must maintain accuracy under thermal variation, high cutting forces, and extended production runs. Robust workholding tooling systems provide the stability required to machine critical features without distortion or drift. As tolerances tighten and quality expectations rise, the importance of well-engineered fixtures becomes even more pronounced.

Optimizing Cost Efficiency Through Better Tooling Strategies

Although custom tooling may require a higher upfront investment, it often delivers long-term cost savings through improved efficiency and reduced waste. Faster setups, shorter cycle times, and fewer rejected parts translate directly into lower per-unit costs. Manufacturing support tooling that aligns with production goals also reduces wear on cutting tools and machines, extending equipment life and minimizing maintenance expenses. Over time, these savings outweigh initial tooling costs, making advanced tooling strategies a financially sound decision.

Cost optimization benefits commonly achieved through advanced tooling include:

-

Lower labor costs due to simplified setups

-

Reduced material waste from fewer rejected parts

-

Improved machine uptime and production scheduling

Integrating Tooling Design With Digital Manufacturing

Modern CNC operations increasingly integrate digital tools such as CAD, CAM, and simulation software into tooling development. This digital approach allows engineers to validate fixture designs virtually before production, identifying potential issues with accessibility, clamping force, or tool interference. By aligning digital workflows with physical tooling, manufacturers can accelerate development cycles and reduce trial-and-error on the shop floor. Digital integration ensures that tooling supports machining strategies rather than limiting them.

The Strategic Value of Partnering With Tooling Specialists

Designing effective tooling requires a deep understanding of machining dynamics, material behavior, and production requirements. Partnering with experienced tooling specialists enables manufacturers to leverage this expertise without diverting internal resources. When companies implement jig and fixture design solutions developed by dedicated professionals, they gain access to proven methodologies and innovative approaches tailored to CNC environments. Such partnerships help ensure that tooling investments deliver measurable performance improvements from the first production run.

Conclusion: Building Reliable CNC Processes Through Advanced Tooling

At the conclusion of any CNC manufacturing strategy, tooling remains a defining factor in overall success. Understanding the foundational principles of jigs and fixtures helps manufacturers appreciate why precise workholding is essential for accuracy and repeatability, as outlined in general manufacturing references such as jigs and fixtures . These foundational concepts provide context for why tooling continues to evolve alongside CNC technology.

As production demands grow more complex, manufacturers benefit from exploring modern approaches to tooling and machining processes, supported by broader CNC knowledge resources like CNC machining reference. By combining foundational knowledge with advanced, application-specific tooling strategies, companies can build CNC processes that are not only precise and efficient but also resilient and scalable for the future.